IoT industrial solutions provider enhancing efficiency

IoT industrial solutions provider stands at the forefront of a technological revolution that is reshaping industries worldwide. As businesses seek to boost operational efficiency, reduce costs, and maintain a competitive edge, the integration of Internet of Things (IoT) technologies has become indispensable. This overview explores the multifaceted benefits and applications of IoT in various industrial sectors, shedding light on its impact and significance.

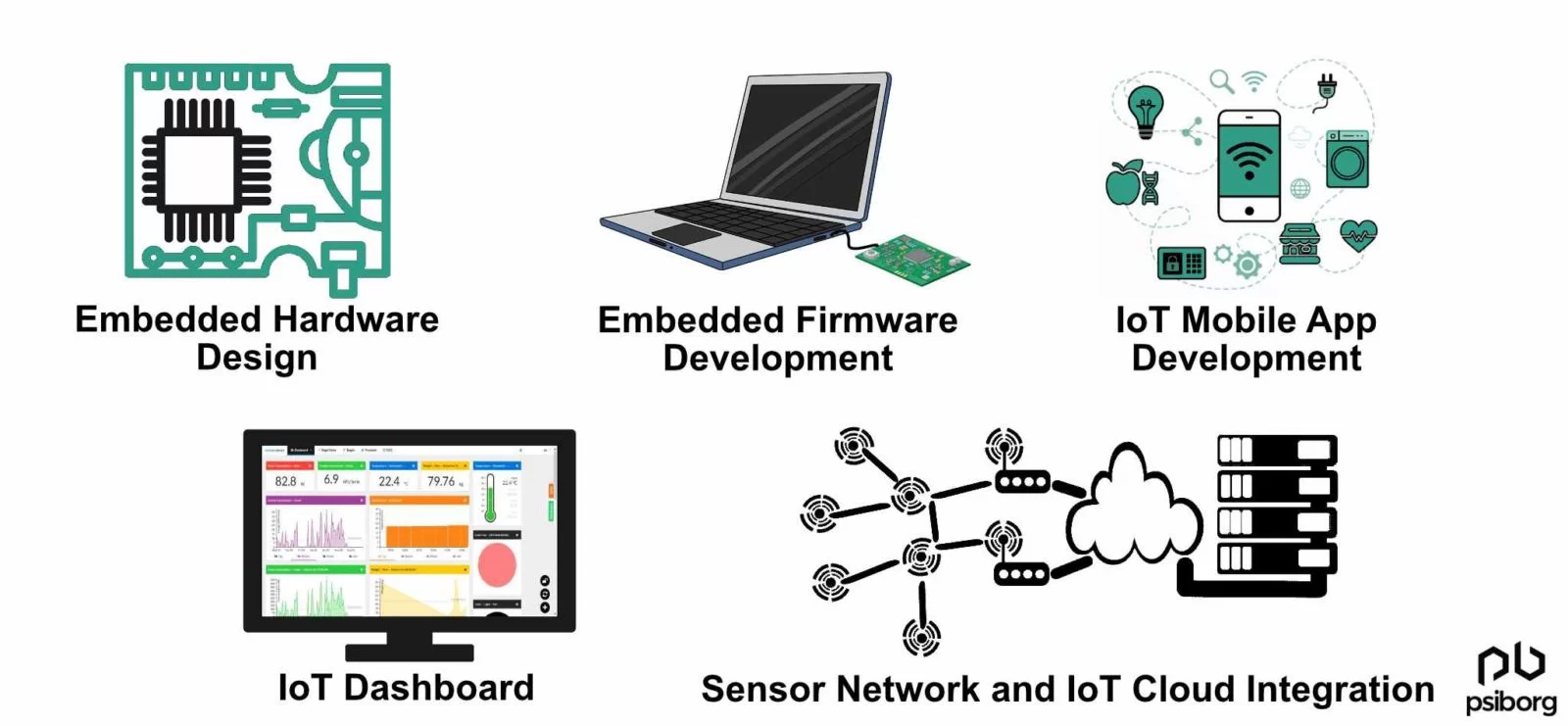

From manufacturing to logistics and agriculture, IoT solutions are designed to address specific challenges faced by these industries. The key components of these solutions encompass devices, connectivity, data analytics, and cloud computing, all working in harmony to streamline processes and improve productivity. By understanding the diverse types of IoT applications and their respective advantages, organizations can make informed decisions to harness the full potential of this transformative technology.

Overview of IoT Industrial Solutions

The Internet of Things (IoT) has emerged as a transformative force in the industrial sector, enabling a new era of connectivity and data-driven decision-making. Within this context, IoT industrial solutions encompass a wide range of technologies and applications that facilitate the seamless integration of devices and systems, leading to enhanced productivity and innovation across industries.IoT in the industrial sector refers to the collection and analysis of data from interconnected devices and systems to improve processes and operations.

By leveraging various technologies, such as sensors, cloud computing, and advanced analytics, organizations can monitor equipment, optimize resource utilization, and predict maintenance needs. This not only streamlines operations but also fosters a proactive approach to management.

Key Components of IoT Industrial Solutions

Understanding the key components of IoT industrial solutions is vital for realizing their potential benefits. The following elements are essential for building robust IoT infrastructures in industrial settings:

- Sensors and Actuators: These devices collect data from machinery and equipment, enabling real-time monitoring of performance parameters. For example, temperature and vibration sensors can help detect anomalies in machinery, facilitating timely maintenance.

- Connectivity: Reliable communication protocols, such as MQTT and CoAP, allow devices to transmit data to cloud platforms or other devices, ensuring seamless information flow across the industrial ecosystem.

- Cloud Computing: Centralized data storage and processing capabilities in the cloud enable organizations to analyze large volumes of data efficiently. This facilitates advanced analytics, machine learning, and data visualization, driving informed decision-making.

- Data Analytics: Analytical tools process the data collected from various sources, uncovering insights that can optimize operations and reduce costs. Predictive analytics, for instance, can forecast equipment failures based on historical data patterns.

- User Interfaces: Dashboards and mobile applications provide users with easy access to real-time data and insights, empowering them to make informed operational decisions quickly.

Significance of IoT in Enhancing Operational Efficiency

The implementation of IoT industrial solutions significantly enhances operational efficiency by enabling organizations to monitor processes in real time and make data-driven adjustments. The following points highlight the impact of IoT on operational efficiency:

- Increased Asset Utilization: IoT solutions monitor machine performance and usage patterns, allowing businesses to optimize asset deployment and reduce downtime.

- Enhanced Predictive Maintenance: By analyzing data from interconnected devices, organizations can predict equipment failures before they occur, minimizing unexpected breakdowns and maintenance costs.

- Improved Supply Chain Management: Real-time visibility into inventory levels and production processes enhances supply chain responsiveness, reducing delays and improving service delivery.

- Energy Efficiency: IoT-enabled devices can monitor energy consumption in real-time, allowing for the identification of inefficiencies and implementation of energy-saving measures.

- Quality Control: Continuous monitoring of manufacturing processes helps maintain product quality and compliance with industry standards, leading to reduced waste and rework.

“The integration of IoT technologies in industrial settings not only drives operational efficiency but also fosters innovation and competitive advantage in the market.”

Types of IoT Industrial Solutions

The Internet of Things (IoT) has revolutionized various industries by providing innovative solutions that enhance operational efficiency, productivity, and safety. The diverse range of IoT industrial solutions caters to specific needs within sectors such as manufacturing, agriculture, and logistics. Each type of solution addresses unique challenges faced by these industries, leveraging data and connectivity to optimize processes.

Manufacturing IoT Solutions

Manufacturing IoT solutions are designed to improve production efficiency, reduce downtime, and enhance quality control. These solutions employ sensors, data analytics, and automation technologies to monitor equipment and processes.

- Predictive Maintenance: This application uses sensors to monitor the health of machinery, predicting potential failures before they occur. For example, General Electric has implemented predictive maintenance in its jet engine manufacturing, resulting in significant cost savings and reduced downtime.

- Smart Manufacturing: Utilizing IoT devices, manufacturers can create interconnected systems that allow for real-time monitoring and adjustments. A notable example is Siemens’ Digital Factory Division, which uses IoT to enhance production flexibility and efficiency.

- Quality Control: IoT solutions facilitate real-time quality monitoring during production. For instance, Bosch employs IoT-enabled cameras in its manufacturing plants to automatically detect defects in products, ensuring high-quality standards.

Agricultural IoT Solutions

Agricultural IoT solutions help farmers optimize yields, manage resources effectively, and improve overall farm productivity. These applications utilize sensors and data analytics to monitor environmental conditions and crop health.

- Precision Farming: This approach utilizes IoT sensors to monitor soil moisture, temperature, and nutrient levels, allowing farmers to make informed decisions on irrigation and fertilization. For example, John Deere’s precision agriculture tools enable farmers to optimize their inputs and increase crop yields.

- Livestock Monitoring: IoT devices are employed to track the health and location of livestock. For instance, smart collars used by companies like Allflex help farmers monitor animal behavior and health, leading to improved herd management.

- Weather Monitoring: IoT applications that provide real-time weather data help farmers plan their planting and harvesting schedules more effectively. For example, the use of weather stations in agriculture allows for timely decisions based on accurate weather forecasts.

Logistics IoT Solutions

Logistics IoT solutions enhance supply chain visibility, improve inventory management, and streamline transportation processes. These solutions rely on connected devices to track goods and assets throughout the supply chain.

- Fleet Management: IoT-enabled GPS tracking systems provide real-time data on vehicle locations, fuel consumption, and maintenance needs. Companies like UPS use such systems to enhance delivery efficiency and reduce operational costs.

- Smart Warehousing: IoT solutions in warehouses automate inventory management through RFID tags and sensors. Amazon’s fulfillment centers utilize IoT technology to optimize storage and retrieval processes, significantly reducing order fulfillment times.

- Cold Chain Monitoring: For perishable goods, IoT sensors monitor temperature and humidity during transport. A practical example is the use of IoT devices by companies like Thermo King to ensure that food products remain within acceptable temperature ranges throughout the supply chain.

Benefits of IoT Industrial Solutions

The adoption of IoT industrial solutions is transforming the way businesses operate, offering numerous advantages that extend beyond mere technological advancements. Organizations are now able to leverage the interconnectedness of devices to optimize processes, enhance decision-making, and drive growth. The benefits of implementing IoT solutions are manifold, encompassing cost savings, improved operational efficiency, and significant returns on investment.Businesses integrating IoT industrial solutions can experience substantial reductions in operational costs and improvements in efficiency through real-time data collection and analysis.

In particular, these solutions enable proactive maintenance, streamline supply chains, and automate routine tasks. The ability to monitor equipment remotely allows for timely interventions, minimizing downtime and extending asset life.

Cost Savings and Return on Investment

The financial implications of adopting IoT industrial solutions are profound, with many organizations reporting significant cost savings and increased returns on investment. Cost savings can be realized through various channels, such as reduced energy consumption, lower maintenance costs, and improved labor efficiency. Notable examples include:

- A manufacturing company that integrated IoT sensors in its production line reported a 20% reduction in energy costs due to optimized machine operations and lower waste output.

- A logistics firm utilizing IoT-enabled tracking devices noted a 15% decrease in fuel expenses by optimizing delivery routes and managing vehicle performance through data analytics.

- Implementing predictive maintenance strategies through IoT technologies led to a 25% reduction in unscheduled downtime for a large industrial plant, resulting in increased production capacity and significant cost savings.

The return on investment (ROI) from IoT implementations can be substantial. According to a study conducted by McKinsey, companies that effectively utilize IoT technologies can expect an ROI of between 15% and 30% over three years. This is often driven by increased operational efficiency and the ability to make more informed business decisions through data insights.

Improvements in Productivity and Efficiency

The impact of IoT industrial solutions on productivity and efficiency is supported by various case studies that highlight substantial gains. The deployment of IoT devices has enabled businesses to streamline their operations and enhance their workflows. For instance, a case study from GE showed that IoT applications in their aviation division led to a 10% increase in operational efficiency due to improved asset utilization and effective maintenance management.Moreover, according to the International Data Corporation (IDC), organizations that adopt IoT technologies can achieve up to a 30% improvement in overall productivity.

This increase is attributed to the ability to gather and analyze data in real-time, allowing businesses to respond swiftly to changes and optimize their processes accordingly.

“Companies leveraging IoT technology are not just enhancing their productivity; they are also paving the way for innovative business models and improved customer experiences.”

In summary, the benefits of IoT industrial solutions extend beyond immediate financial gains. The integration of these technologies fosters a culture of continuous improvement and innovation, positioning businesses to thrive in a competitive landscape.

Challenges in IoT Implementation

The implementation of Internet of Things (IoT) solutions in industrial settings presents various challenges that organizations must navigate to achieve successful integration and operation. While the potential benefits of IoT are significant, the complexities and hurdles associated with deployment can hinder progress and adoption. Understanding these challenges is essential for companies aiming to leverage IoT technology effectively.One of the most pressing difficulties faced by companies involves the integration of IoT devices into existing systems.

Organizations often operate with legacy systems that may not be compatible with modern IoT technologies. This can lead to significant technical hurdles that require thoughtful planning and execution. Moreover, the interoperability of devices from different manufacturers can create complications in maintaining a cohesive ecosystem.

Security and Privacy Concerns

The proliferation of IoT devices raises significant security and privacy issues that organizations must address diligently. Given that IoT devices often collect, transmit, and process sensitive data, protecting this information is paramount. Businesses face various risks associated with potential data breaches and cyber-attacks that could exploit vulnerabilities within their IoT infrastructure.The following points Artikel key security and privacy concerns related to IoT devices:

- Data Encryption: Ensuring that data transmitted over networks is encrypted to prevent unauthorized access.

- Device Authentication: Implementing robust authentication methods to verify the identity of devices connecting to the network.

- Regular Updates: Keeping firmware and software up to date to protect against known vulnerabilities.

- Access Controls: Establishing strict access controls to limit who can interact with IoT devices and the data they handle.

As organizations navigate these challenges, it is crucial to develop a comprehensive security strategy that encompasses all aspects of IoT deployment.

Technical Hurdles in Integration

Integrating IoT solutions with existing systems often entails several technical challenges that require specialized knowledge and resources. These hurdles can delay implementation timelines and increase costs if not managed properly. Companies must consider the architecture and compatibility of new IoT solutions with their current infrastructure.Key technical challenges include:

- Data Standardization: The lack of common standards can lead to difficulties in data sharing and communication between devices.

- Scalability Issues: As IoT deployments grow, ensuring that systems can scale effectively without degradation in performance is critical.

- Network Reliability: Establishing a reliable network infrastructure that can support the high volume of data generated by IoT devices.

- Real-time Processing: Implementing systems capable of real-time data processing and analytics to derive actionable insights promptly.

Addressing these technical hurdles requires a strategic approach, including thorough planning, investment in the right technologies, and fostering collaboration among various stakeholders within the organization.

Future Trends in IoT Industrial Solutions

As the landscape of industrial operations continues to evolve, the Internet of Things (IoT) is emerging as a critical enabler of innovation and efficiency. The future of IoT in industrial solutions is marked by a convergence of advanced technologies, offering unprecedented opportunities for automation, data analysis, and operational optimization. This segment explores key emerging trends that are shaping the future of IoT in the industrial sector, emphasizing the integration of artificial intelligence and machine learning as transformative forces.

Emerging Trends in IoT Technologies

The integration of IoT technologies within industrial applications is advancing rapidly, driven by several key trends. These trends include the proliferation of edge computing, enhanced connectivity through 5G networks, and the increasing adoption of digital twins.

- Edge Computing: By processing data closer to the source, edge computing minimizes latency and bandwidth usage, allowing real-time decision-making and analysis. This trend is particularly significant for applications requiring immediate responses, such as predictive maintenance and quality control.

- 5G Connectivity: The rollout of 5G technology enables faster data transmission and improved reliability, facilitating the connection of numerous devices simultaneously. This enhanced connectivity supports the deployment of smart factories and real-time analytics.

- Digital Twins: Creating virtual replicas of physical assets allows for simulation, monitoring, and analysis of performance. Industries can leverage digital twins for optimizing operational efficiency and predicting equipment failures.

Role of Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) play pivotal roles in the evolution of IoT industrial solutions. By harnessing vast amounts of data generated by connected devices, these technologies enable predictive analytics, automation, and improved decision-making processes.

“AI and ML empower industries to unlock the full potential of IoT by automating complex tasks and providing actionable insights from data.”

The incorporation of AI and ML facilitates:

- Predictive Maintenance: Utilizing algorithms to analyze data from machinery and predict failures before they occur, reducing downtime and maintenance costs.

- Quality Control: Implementing real-time monitoring and analysis of production processes to ensure that quality standards are consistently met.

- Supply Chain Optimization: Analyzing patterns and trends in supply chain data to enhance inventory management and streamline logistics.

Predictions on the Future of IoT in the Industrial Landscape

Looking ahead, the impact of IoT on the industrial landscape is expected to be profound, with several predictions indicating a transformative shift in operational dynamics.

- Increased Adoption of Automation: As companies continue to seek efficiency, the usage of autonomous systems and robots in manufacturing is likely to grow, leading to more streamlined operations.

- Expansion of Smart Factories: The concept of smart factories, where machines communicate and cooperate with one another, is anticipated to become a standard, enhancing flexibility and customization in production.

- Enhanced Cybersecurity Measures: With the growth of connected devices, the emphasis on robust cybersecurity protocols will intensify to protect sensitive data and prevent breaches.

- Integration of Sustainability Practices: IoT will increasingly be utilized to monitor and reduce energy consumption and waste in industrial processes, aligning with global sustainability goals.

As these trends continue to unfold, organizations that embrace IoT innovations will be well-positioned to enhance their competitiveness, operational efficiency, and adaptability in an ever-evolving industrial landscape.

Selecting the Right IoT Industrial Solutions Provider

In the rapidly evolving landscape of IoT industrial solutions, choosing the right provider is a critical decision that can significantly influence the success of an enterprise’s digital transformation initiatives. The selection process must be thorough and strategic, focusing on various factors that ensure the provider aligns with the organization’s specific needs and operational goals.Evaluating potential IoT solution providers involves several key criteria that guide organizations towards making informed decisions.

These criteria encompass various aspects, including technology capabilities, industry experience, and customer support services. The following points elaborate on essential factors to consider when evaluating IoT solution providers.

Criteria for Evaluating IoT Solution Providers

The selection of an IoT provider should be based on multiple criteria that reflect the organization’s requirements and the provider’s capabilities. Key criteria to consider include:

- Technical Expertise: Assess the provider’s knowledge of IoT technologies, including hardware, software, and connectivity. Their ability to integrate with existing systems is crucial.

- Industry Experience: A provider with experience in your specific industry can better address unique challenges and offer tailored solutions.

- Scalability of Solutions: Evaluate whether the solutions offered can grow alongside your business needs, accommodating future expansions seamlessly.

- Security Measures: Review the provider’s approach to data security and privacy, as IoT systems are often vulnerable to cyber threats.

- Compliance with Standards: Ensure that the provider adheres to relevant industry regulations and standards, which can mitigate risks associated with legal compliance.

- Customer Support Services: Strong, reliable support services are essential for addressing issues that may arise post-implementation. Evaluate the responsiveness and availability of their support team.

- Cost-Effectiveness: Compare the pricing structures of different providers to ensure that you receive value for your investment without compromising on quality.

The importance of vendor reliability and support services cannot be overstated in the context of IoT implementations. A dependable provider not only ensures that the deployment process is smooth but also guarantees ongoing support that can help resolve technical issues quickly. Furthermore, investing in a provider with robust support services can lead to improved operational efficiency and minimized downtime, thereby enhancing productivity.

Vendor Reliability and Support Services, IoT industrial solutions provider

Choosing a vendor with a proven track record of reliability is crucial for long-term success in IoT projects. A reliable vendor should demonstrate:

- Established Reputation: Look for providers with positive reviews and testimonials from existing clients, showcasing their reliability and quality of service.

- Service Level Agreements (SLAs): Review the SLAs that Artikel the level of service expected, including response times and resolution times for support issues.

- Training and Resources: A good provider offers training programs and resources to help your team effectively utilize their IoT solutions.

Additionally, the provider’s market presence and the breadth of their offerings play a significant role in your decision-making process. A provider with a strong market presence often indicates stability and reliability, while a diverse range of offerings can ensure that they can meet various needs as they arise.

Comparing Various IoT Providers

When comparing IoT providers, it is essential to examine their market presence and the specific solutions they offer. Some of the leading players in the IoT industrial solutions space include:

- Siemens: Known for their comprehensive industrial automation solutions, Siemens offers robust IoT platforms that enhance manufacturing efficiency.

- GE Digital: With a focus on industrial IoT, GE Digital provides solutions that improve operational efficiency and predictive maintenance.

- IBM: IBM’s Watson IoT platform leverages advanced analytics and machine learning to deliver actionable insights from connected devices.

- PTC: PTC specializes in IoT solutions that integrate with augmented reality, helping industries visualize data and improve operations.

- Microsoft Azure IoT: This platform offers extensive capabilities for building and deploying IoT applications that integrate seamlessly with existing Microsoft services.

Understanding the strengths and offerings of each provider will allow organizations to make decisions that align with their strategic objectives and operational requirements. By carefully assessing the criteria of technical expertise, industry experience, and support services, companies can select an IoT industrial solutions provider that will drive innovation and efficiency in their operations.

Case Studies of Successful IoT Implementations

The implementation of IoT solutions in industrial settings has proven to yield significant improvements across various sectors. By examining successful case studies, we can learn valuable insights into best practices, challenges faced, and the measurable benefits realized post-implementation. This exploration not only highlights the transformative power of IoT but also underscores the importance of strategic planning and execution in leveraging these technologies effectively.

Case Study 1: General Electric – Digital Wind Farm Initiative

General Electric (GE) embarked on a remarkable initiative to enhance energy production at its wind farms through IoT solutions. The company faced challenges related to optimizing the performance of wind turbines and maximizing energy output. By integrating IoT sensors and analytics, GE was able to monitor turbine performance in real-time.The collected data facilitated predictive maintenance and performance optimization, leading to a 10% increase in energy capture across its wind farms.

GE utilized advanced algorithms to analyze patterns and predict failures before they occurred, thereby reducing downtime and maintenance costs.

“With IoT, we have turned our wind farms into digital enterprises, allowing us to harness data for greater efficiency.”

General Electric

Case Study 2: Siemens – Smart Manufacturing

Siemens implemented IoT technology in its manufacturing processes to create a smart factory environment. The company faced issues related to equipment inefficiencies and production delays. By deploying IoT-enabled devices and systems, Siemens gained real-time visibility into its manufacturing operations.The outcome was a 20% increase in production efficiency and a significant reduction in operational costs. Siemens leveraged digital twins and IoT analytics to streamline workflows and enhance communication across different factory segments.

This integration allowed for better decision-making based on real-time insights, ultimately boosting productivity.

“The integration of IoT into our manufacturing processes has allowed us to optimize operations and reduce costs significantly.” – Siemens

Case Study 3: Bosch – Connected Logistics

Bosch faced challenges in managing its supply chain logistics effectively. To address inefficiencies, the company adopted IoT solutions that enabled real-time tracking of shipments and inventory levels. By implementing connected devices throughout the supply chain, Bosch was able to gather critical data regarding the movement and status of goods.This initiative led to a 15% reduction in logistics costs and improved delivery times by 25%.

The use of IoT not only enhanced visibility but also allowed Bosch to respond swiftly to any disruptions, ensuring a more resilient supply chain.

“Utilizing IoT in our logistics has transformed how we manage supply chain operations, leading to cost savings and improved service levels.” – Bosch

Case Study 4: Caterpillar – Predictive Maintenance

Caterpillar, a leader in heavy equipment manufacturing, implemented IoT solutions to enhance its predictive maintenance capabilities. The company encountered challenges with unexpected equipment failures that resulted in costly downtime. By integrating IoT sensors into its machinery, Caterpillar gained insights into equipment health and performance metrics.This proactive approach to maintenance led to a 30% reduction in unplanned downtime and allowed for more efficient scheduling of maintenance activities.

The measurable outcome was a significant increase in equipment availability, which translated into higher productivity levels for customers.

“Through IoT, we have transformed our maintenance practices, empowering our clients with improved uptime and efficiency.” – Caterpillar

Best Practices for IoT Industrial Solutions Deployment

The deployment of IoT industrial solutions is a multifaceted process that requires careful planning and execution. By following best practices, organizations can maximize the benefits of IoT while minimizing potential disruptions. Effective deployment not only enhances operational efficiency but also fosters a culture of innovation and adaptability within the workforce.Key to the success of any IoT implementation is the emphasis on staff training and change management.

An informed and skilled workforce is essential in leveraging new technologies effectively. Transitioning to IoT-enabled systems often requires a shift in mindset and operational processes, making it imperative to invest in comprehensive training programs. Change management strategies must be established to facilitate this transition, addressing employee concerns and fostering an environment receptive to technological advancements.

Importance of Staff Training and Change Management

Investing in staff training ensures that employees are well-equipped to operate and maintain new IoT systems. This involves not just technical training but also education on the strategic importance of IoT in achieving organizational goals. Effective change management strategies should include:

- Assessing current skill levels and identifying gaps in knowledge related to IoT technologies.

- Developing tailored training programs that address specific roles and responsibilities.

- Encouraging a culture of continuous learning, where employees are motivated to upskill regularly.

- Incorporating hands-on training sessions and simulations to provide practical experience.

Change management is equally critical as it helps to smooth the transition to new systems. Strategies may involve:

- Communicating the benefits of IoT adoption clearly to all levels of staff to build buy-in.

- Engaging employees in the planning and implementation process to foster ownership and accountability.

- Providing ongoing support to address challenges and adapt to evolving technologies.

- Measuring and celebrating small wins to maintain enthusiasm and encourage further adoption.

Checklist for Organizations During IoT Implementation

To facilitate a smooth IoT deployment, organizations can benefit from following a structured checklist. This list encompasses critical steps and considerations that should be addressed prior to and during implementation:

- Define clear objectives for the IoT implementation, aligning them with business goals.

- Conduct a thorough assessment of existing infrastructure and determine necessary upgrades.

- Involve cross-functional teams early in the planning process to ensure comprehensive insights.

- Evaluate potential IoT solutions for scalability, security, and compatibility with existing systems.

- Establish robust data management practices, including data collection, storage, and analysis protocols.

- Develop a cybersecurity strategy to protect against potential vulnerabilities in connected devices.

- Implement pilot programs to test IoT solutions before full deployment, allowing for adjustments.

- Set performance metrics and KPIs to assess the effectiveness of the IoT solution post-implementation.

Answers to Common Questions: IoT Industrial Solutions Provider

What is IoT in the industrial sector?

IoT in the industrial sector refers to the integration of internet-connected devices that collect and exchange data, leading to improved operational efficiency and decision-making.

What are the benefits of IoT industrial solutions?

The benefits include enhanced operational efficiency, cost reduction, improved productivity, and data-driven decision-making.

What industries can benefit from IoT solutions?

Industries such as manufacturing, agriculture, logistics, and healthcare can significantly benefit from IoT solutions.

What are the common challenges in implementing IoT solutions?

Common challenges include security and privacy concerns, technical integration with existing systems, and resistance to change from staff.

How can businesses choose the right IoT solution provider?

Businesses should evaluate providers based on their reliability, support services, market presence, and the specific solutions they offer that align with business needs.